As manufacturing enters the Industry 4.0 era, the demand for fast, secure, and reliable connectivity between factory-floor operations and enterprise systems has become critical. Private 5G networks are emerging as a powerful enabler, offering low latency, strong security, and seamless integration of real-time data from machines and sensors into ERP platforms for smarter, faster decision-making. This convergence of operational and information technologies is unlocking new possibilities for automation, efficiency, and safety across industries.

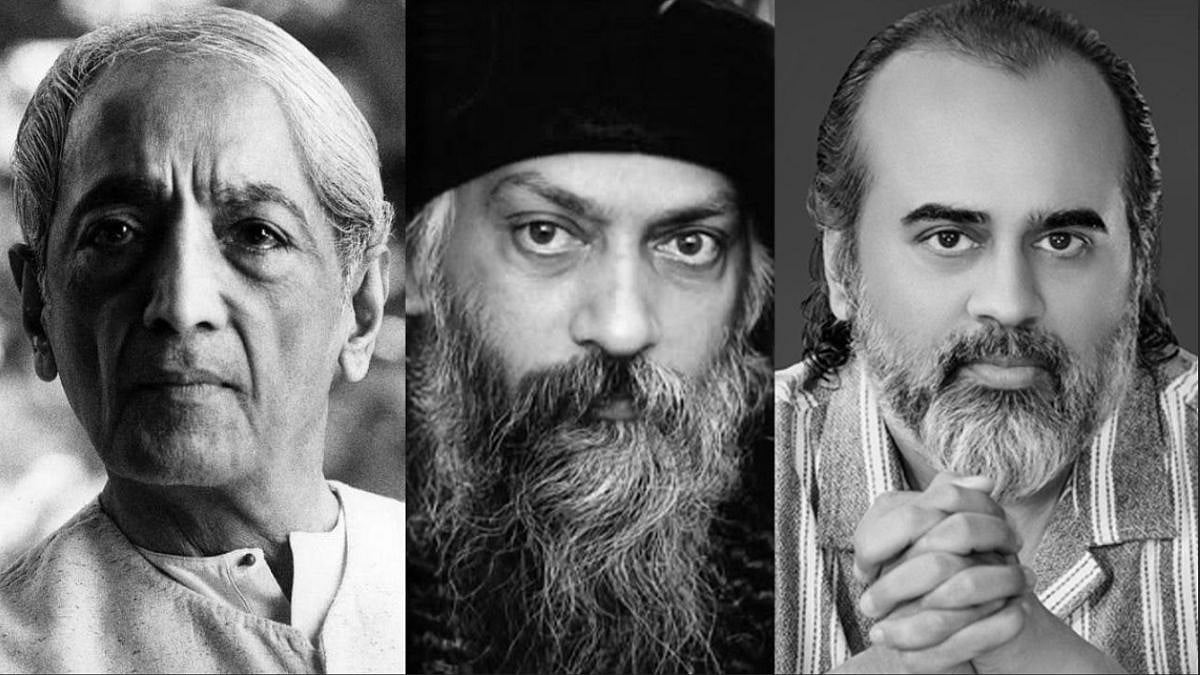

Assisting this shift is telecom innovator Rahul Bangera, a pioneer in integrating dedicated industrial networks with core business systems to close the industrial connectivity loop. Rahul has extensive experience designing advanced private wireless architectures for complex manufacturing sites. He focuses on secure, on‑premise systems that connect factory operational technology (OT) with enterprise IT environments.

This matters because machines and sensors on the factory floor generate large amounts of real-time data. The engineer’s solutions make it easy for this data to flow directly into integrated management platforms like SAP. Under his leadership, multi-site deployments have transformed such solutions from passive data repositories into live, decision-driving engines.

Beyond building advanced network frameworks, the specialist has addressed two major hurdles in industrial wireless adoption: workforce readiness and cybersecurity. Many organisations lack in-house cellular expertise, making implementation complex and risky.

To resolve differences, the strategist has developed comprehensive managed services that provide 24/7 support for network operations, device certification, and system integration. This approach removes key operational barriers and speeds up technology adoption.

The benefits are evident. Leading petrochemical and chemical manufacturers have reported improved inventory accuracy, enhanced worker safety through AI-powered devices, and cost savings derived from real-time operational data. His approach balances innovation with practical deployment, ensuring solutions remain secure, scalable, and closely aligned with strategic objectives.

However, from the expert’s experience working on large-scale deployments, the real value lies in making technology invisible to the people who use it.

Operators, engineers, and decision‑makers shouldn’t have to think about the underlying network; they should simply have access to accurate, real-time information wherever they are. When machines can instantly “communicate” with business systems, decisions that used to take hours or days can happen in minutes.

This means fewer production delays, safer work environments, and the flexibility to adapt quickly to changes in demand or supply. The aim is not just to connect systems, but to create an environment where information moves effortlessly to the right people at the right time.

Looking ahead, the convergence of secure industrial connectivity, edge computing, and artificial intelligence is set to redefine industrial operations. These integrated systems will enable self-optimising, intelligent factories capable of predictive maintenance, robotics control, and real-time worker assistance.

In this vision, centralised enterprise systems powered by advanced private networks will serve as the nervous system of manufacturing operations, delivering unmatched agility and competitiveness.

Moving forward, according to the expert, “Private 5G is more than a technology; it is the foundation for turning manufacturing data into actionable intelligence, unlocking the potential of Industry 4.0 and beyond.”

The growing adoption of dedicated connectivity platforms is reshaping industrial operations, enabling faster data flow, improving efficiency, and making systems more adaptable.

This progress relies on the right balance of cutting-edge infrastructure and skilled human oversight, closing the loop between machines, data, and decision‑makers, and paving the way for the next wave of manufacturing innovation.