Coronavirus has disrupted the global supply chains and has left the world vulnerable to severe shortage issues. The aviation industry has had the biggest impact of all from the COVID-19 crisis resulting in a complete shutdown. Experts fear that the sector is in jeopardy and its survival is at stake.

To bring the industry out of its ruins, experts are betting big on 3D printing technology to save the aviation industry. The technology will save costs across the entire supply chain and also make the supply chains efficient than ever before.

3D printing, also known as additive manufacturing, is a revolutionary manufacturing technology that produces a three-dimensional solid object from a digital 3D CAD file in a continuous layer-by-layer process. It is a unique manufacturing technology that can rapidly manufacturing complex designs previously not possible.

We explore how the aviation industry can implement additive manufacturing technology to create a significant amount of value.

AVIATION INDUSTRY: IMPLEMENTING ADDITIVE MANUFACTURING TECHNOLOGY

Mini-Factories in the Hangar

A380 inside hangar | Etihad Engineering

Professional quality additive manufacturing systems are now available in all sizes like desktop, benchtop, and even large formats. These systems can work efficiently to rapidly manufacture high-performance tooling, replacement, production aids, or end- use parts used in the maintenance of the planes right in the hanger. The mini-factories can even service occasionally arriving planes and whose spare parts are not stocked.

In-House Quality Control

With additive manufacturing systems in place, a lot of parts previously outsourced can be brought in-house. For critical sectors like defence, essential parts can be brought in- house and strictly quality controlled. This will also help in reducing the costs by eliminating the middlemen, eliminating the supply chains for the selected parts, and also eliminating the supply chain costs & time lags.

Single-Part Capability

3D printing can economically produce even a single-part. The aviation industry is ruled by low volume production and 3D printing can perfectly fit in the overall scheme of things where a majority of the products are 3D printed while a selected few are traditionally manufactured. Such a balance will serve well for achieving operational efficiencies.

Flight-Ready Parts

Additive manufacturing of borescope eyes for the geared turbofans of the new PurePower® PW1100G-JM engine generation of the Airbus A320neo | EOS

A lot of companies have qualified the 3D printers, materials, the processes, and even certain parts that can be 3D printed to be used in a commercial or military flight. This can be leveraged and such parts can be easily eliminated from stocking and just digital files are stored. These can be 3D printed whenever required. This saves a huge warehousing cost, maintenance costs, saves time.

BENEFITS OF AM TO THE AVIATION INDUSTRY

Short Product Development Cycle

Additive manufacturing is known for its capability to rapidly manufacture complex industrial-grade parts. It can eliminate tooling and significantly reduce the entire manufacturing workflow. The entire supply chain can be shortened and parts can be manufactured right at the point of its use.

Part Consolidation & Light-weighting

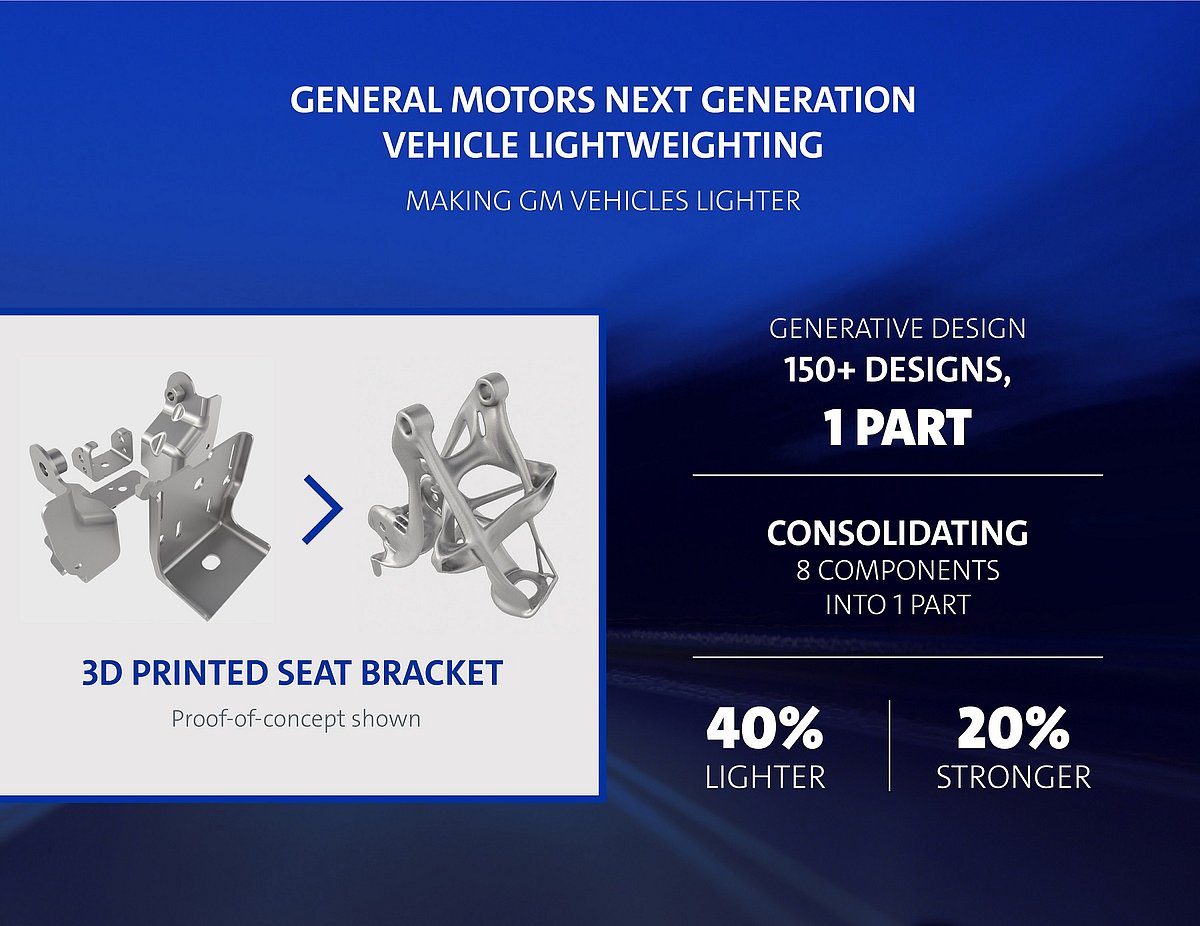

Seat bracket was consolidated from 8 parts to a single piece | General Motors

Companies are using 3D printing to consolidate multiple parts into a single piece and also use generative design software to create a complex design to reduce the weight of the parts being 3D printed. The resulting benefits are reduced weight, better performance, and better system efficiency.

This benefit of the AM technology can be leveraged to reduce costs and run the current systems more efficiently.

Leveraging Specialised Materials

Some materials like titanium (Ti6Al4V) used in the aviation industry offer significant benefits to the flight systems. But titanium is an expensive material. Moreover, it is difficult to machine leading and complex design can further increase its production time and costs. But additive manufacturing brings efficiency to the production process as such an expensive material is used judiciously with negligible wastage. AM can also manufacture generatively designed parts to further reduce material usage and improve performance. This can also save a lot of costs.

Value Addition

Additive manufacturing can impact the product development cycle by adding value to each part of the supply chain. Right from design & prototyping to its production at the plant level and even for after-sales support, additive adds value to the entire process.

Reduced Warehousing Costs

Aviation warehousing can be reduced through the use of AM systems | KORR

The additive manufacturing of replacement parts has a direct impact on the need for stocking of parts. By carefully identifying and qualifying replacement parts that can be manufactured through 3D printing, a huge assortment of parts can be produced on-demand. This reduces the load on warehouses to save operational costs.

Time & Cost Savings

All the above-mentioned benefits one way or the other result in immense time and cost savings. The current crisis has put an added onus on time and cost-saving initiatives and additive manufacturing can deliver the results as are the need of the hour right now.

CONCLUSION

Additive manufacturing is a natural fit for the aviation industry due to its capability to incorporate part consolidation, light-weighting. Besides this, non-essential (sometimes even the essential) goods can be printed on-demand to save costs and reduce stocking.

Companies will have to adopt such measures to ensure the company and the overall industry survives and additive manufacturing can pave the way into the ‘Post-COVID- 19’ world.

For more such articles, please visit: http://www.manufactur3dmag.com